Save up to 40% on Overstock XPress Drilled Complete Mold Plates!

While Supplies Last!

Smart Series® Me Hot Runner Temperature Controllers

Simple… Powerful… Compact… Robust

servomold® Unscrewing Device

Precision, Reliability and Durability Come Standard… Simplify and Automate Your Mold

Our Products

Services

Hot Runner Service Center

From repairs and system cleaning to total system rebuilds and mold tryouts, DME is the single hot runner maintenance & optimization source – Click here to learn more.

Temperature Control Repairs & Calibration

DME offers repair services for all of our temperature control mainframes, modules and fully integrated units – Click here to learn more.

Applications Engineering Services

The DME Applications Engineering Department is focused on one thing – to help you produce better parts – Click here to learn more.

Moldflow Services

DME uses Moldflow Plastics Insight software, an integrated suite of analysis tools, to enable a virtual ‘what if’ design environment before beginning mold construction – Click here to learn more.

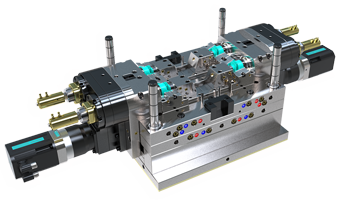

Machining Services

DME has a breadth of machining capabilities to custom manufacture to your exact designs, from large to small freeing up your resources to work on high value core and cavities – Click here to learn more.

Barrel Resleeving & Repair

DME offers a high-quality alternative to competitive barrel resleeving and repair options with fast turnaround time to maximize your uptime – Click here to learn more.

Get In Touch